Certyfikacja ISO/TS 22163

The railway industry is undergoing major changes. Privatisation and restructuring of enterprises, globalisation, increasing quality and technical requirements and legislation are all contributing to changes in the railway industry.

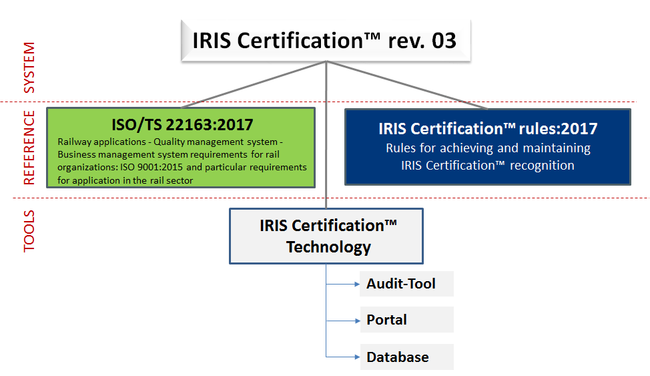

The latest revision of IRIS rev. 03 came into force on 1 June 2017 under the name IRIS Certification ™ rev. 03. ISO/TS 22163:2017 is owned by International Standard Organisation and it covers the requirements of ISO 9001, but augments these with specific requirements for the railway industry. IRIS Certification ™: 2017 is owned by UNIFE and contains all relevant principles for the assessment methodology and certification process.

On 24 May 201 Unife published a new revision of the IRIS standard as ISO/TS 22163:2017 "Railway applications - Quality management system - Business management system requirements for rail organizations: ISO 9001:2015 and particular requirements for application in the rail sector", which has become the new global standard for quality management systems in the railway sector.

IRIS certification - international standard for the railway industry

ISO/TS 22163:2017 supplements ISO 9001:2015 for specific requirements related to railways. Comparable to automotive or aerospace industry standards.

Rail vehicle suppliers and manufacturers have the opportunity to be audited and certified by independent, UNIFE-recognised certification bodies. TÜV NORD is among the first certification companies to have an accreditation agreement with the UNIFE/IRIS Group. ISO/TS 22163:2017 certification is based on the well-known EN ISO 9001:2015 certification. The audit assessment, in contrast, is based on a scoring procedure that gives companies a differentiated assessment of their management system.

What are the benefits of ISO/TS 22163 certification?

- Improvement of quality standards in the company and the whole supply chain - ongoing control and monitoring of the quality management system - in case of insufficient maturity of a system component the standard imposes the necessity to implement corrective actions (time period of 90 days) or improving actions (time period of 12 months)

- Cost and effort reduction - ISO 9001:2015 and ISO/TS 22163:2017 certification

- IRIS database- increases the transparency of information about suppliers in the railway industry; only a company certified to ISO/TS 22163:2017 is registered in the European IRIS database, which provides information about entities that meet the specific requirements that the railway industry sets for its manufacturers and suppliers

- Less system audits - agreement of the largest corporations in the market to recognise the requirements of the standard as valid in the assessment of their sub-suppliers and to recognise its results

Why work with us?

TÜV NORD is an international certification body with extensive experience in the certification of management systems. We offer you internationally recognised certification according to the IRIS standard, which enables integration with other management systems. All companies certified to ISO/TS 22163:2017 are listed in the IRIS database which is available to all market participants.

https://www.iris-rail.org/index.php

Our auditors are skilled professionals with specific additional qualifications in ISO/TS 22163:2017

What does the certification path look like?

- Interview and filling in the questionnaire

- Preparation of an offer

- Application for certification according to ISO/TS 22163:2017

- Evaluation of management system documentation

- On-site audit including report

- Issue of ISO/TS 22163:2017 certificate

- Entry in the IRIS database

We also offer a full range of training courses specific to the rail industry. These trainings cover the topics of the IRIS standard and are related to other industry requirements.

Examples of training courses on the IRIS standard:

- Quality Management System requirements according to the IRIS standard

- internal auditor according to ISO 9001 and ISO/TS 22163:2017 requirements

- Risk analysis based on FMEA and FMECA

- RAMS, LCC - methodology, indicators and criteria for the product life cycle in an organisation

We invite you to contact us